Services

What can we do for you?

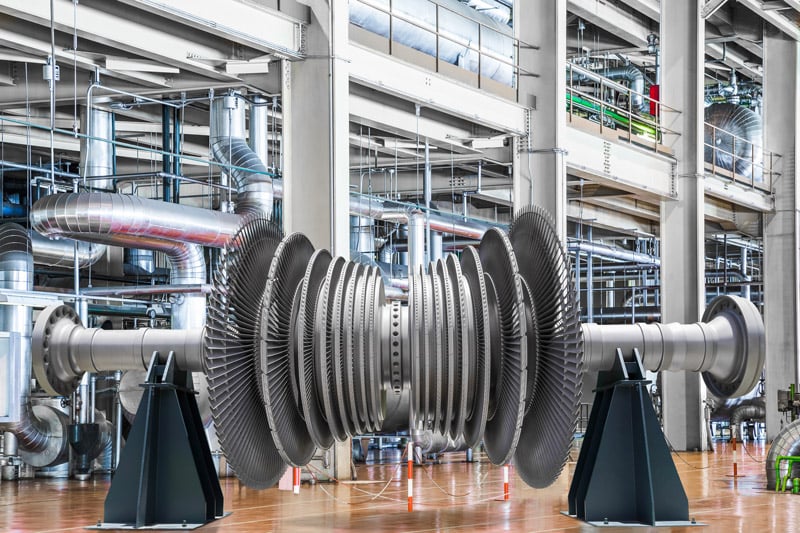

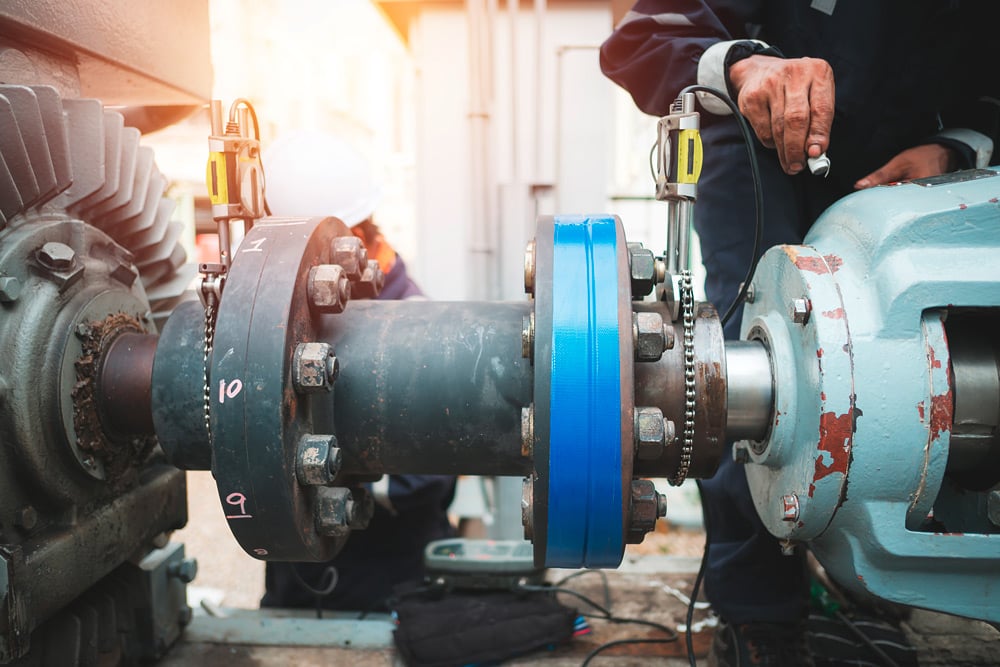

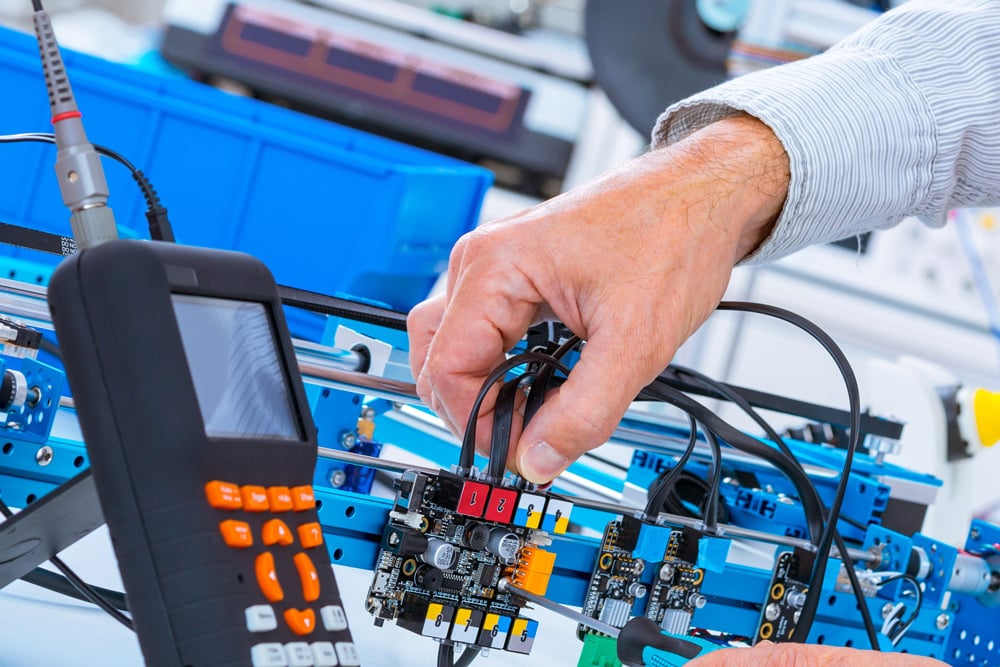

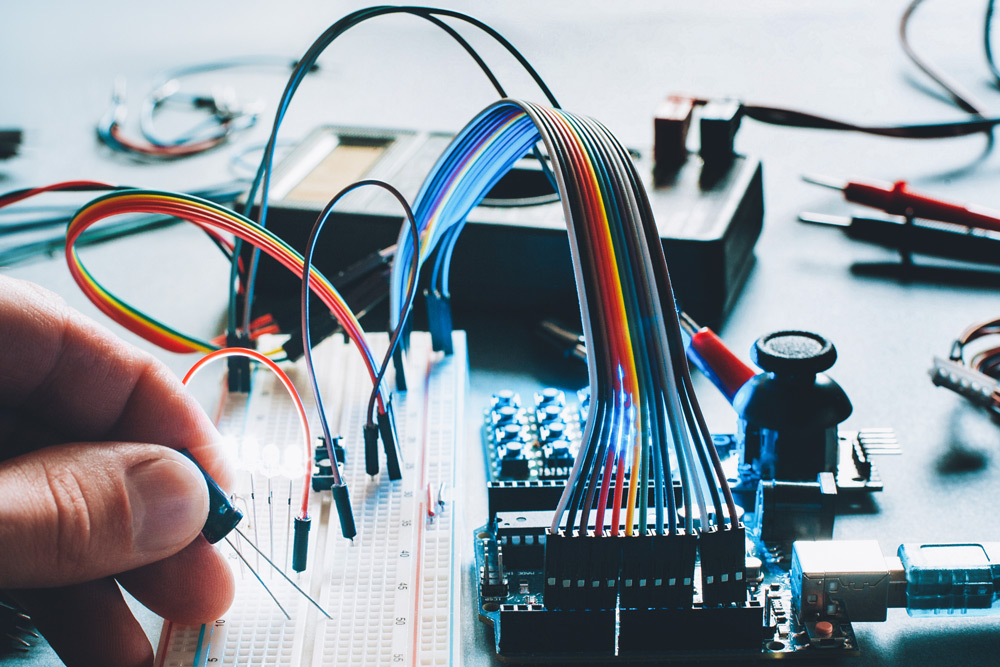

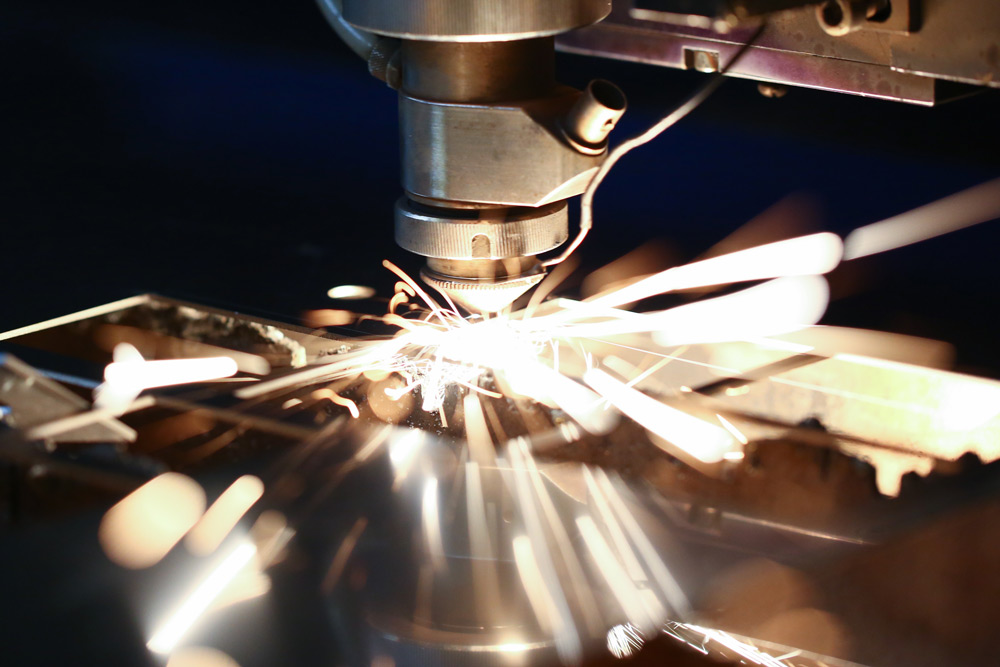

The selection, installation and maintenance of test and measuring equipment require special care and know-how. This applies all the more in critical applications, e.g. in power plants or large industrial machines. We offer you numerous technical services through our mobile team and our in-house laboratory to power plants and industrial customers worldwide: