Magnetostrictive Sensor MRG

Non-contact linear displacement transducer based on magnetostrictive technology, designed for harsh use in industrial environments. Non-contact and thus wear-free operation with unlimited mechanical life.

Different analogue output signals available with direct or inverted signal, thus high flexibility in application with simultaneously very good measuring accuracy in terms of non-linearity, repeatability and hysteresis.

- Nominal stroke from 150 ... 1500mm

- High resolution of less than 1µm

- Non-contact, wear-free operation

- High signal strength and very good signal stability

- Shock resistant / Schick tested up to 100g

- Robust stainless steel housing, protection class IP67

- Compatible with sensors from BALLUFF and MTS

Technical data

|

MRG

|

|||

|

Nominal measuring range

|

150 - 1500 mm

|

||

|

Linearity

|

< 0,05 % F.S. / min. 100 µm

|

||

|

Resolution

|

< 1 µm

|

||

|

Repeatability

|

< 20 µm

|

||

|

Hysteresis

|

< 10 µm

|

||

|

Sampling rate

|

1,5 ms

|

||

|

Supply voltage

|

19...30 VDC

|

||

|

Power consumption

|

< 40 / 80 mA

|

||

|

Polarity protection

|

yes

|

||

|

Surge protection

|

yes

|

||

|

Output signal

|

Standard: 4 ... 20 mA / 20 ... 4 mA

optional: 0...10 V or 10 ... 0 V

|

||

|

Pressure resistance

|

350 bar

|

||

|

Case material

|

Stainless steel AISI 316

|

||

|

Operating temperature

|

-20 ... +75 °C

|

||

|

Drift

|

< 0,01 % F.S./K

|

||

|

Protection (DIN 40050)

|

IP 67

|

||

|

Signal on error

|

21 mA resp. 10,5 V

|

||

|

Type of installation

|

Thread M18 x 1,5

|

||

|

Seal

|

O-ring 15,4 x 2,1 SH90

|

||

|

Zero position

|

47,5 mm (Minimum distance)

|

||

|

Shock test

|

RL

|

DIN IEC68T2-27 - 100 g / 11 ms

|

|

|

Vibration test

|

DIN IEC68T2/6 - 12 g / 10...2000 Hz

|

||

|

Conformity

|

EMC according to EN 61000 / RoHS

|

Special designs on request

Do you have further technical questions about the product?

We will be happy to help you determine the order code and provide you with further specific information for your required product.

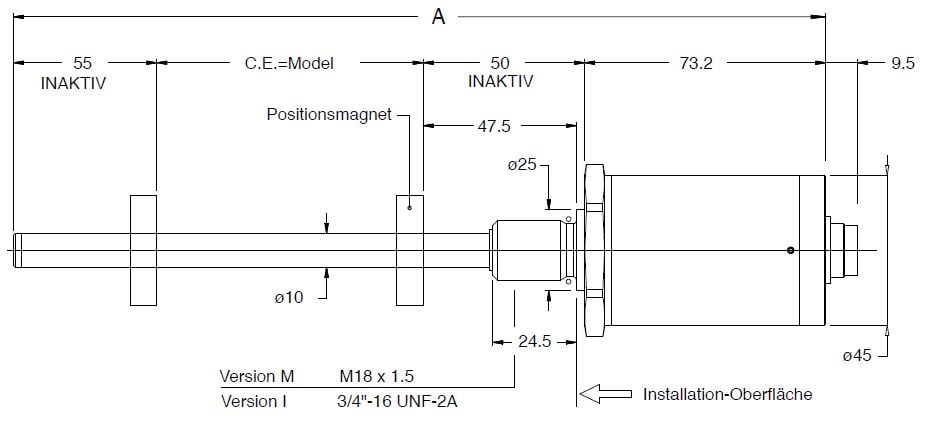

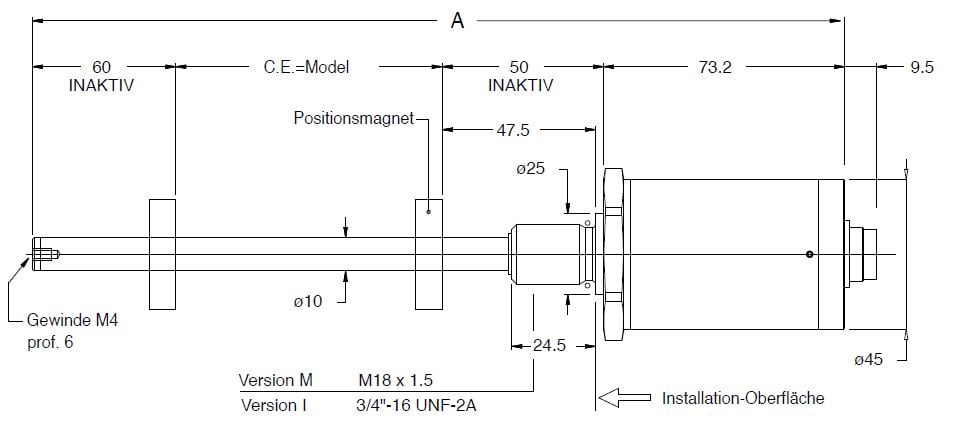

Installation and connection dimensions

| MRG 150 |

MRG 200 |

MRG 250 |

MRG 300 |

MRG 400 |

MRG 500 |

MRG 600 |

MRG 800 |

MRG 900 |

MRG 1000 |

MRG 1250 |

MRG 1500 |

||

| Nominal stroke | mm | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 800 | 900 | 1000 | 1250 | 1500 |

| Working span mech. | mm | > 200 | > 250 | > 300 | > 350 | > 450 | > 550 | > 650 | > 850 | > 950 | > 1000 | > 1250 | > 1500 |

| Installation length (plus connector) | mm | 330 | 380 | 430 | 480 | 580 | 680 | 780 | 980 | 1080 | 1180 | 1435 | 1685 |

| Inactive area | mm | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 | 47,5 |

| Magnet-AD (Vers. A+B) | mm | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 | 32,8 |

| Magnet-AD (Vers. C) | mm | 25,4 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 |

| Magnet-ID (Vers. A,B,C) | mm | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 | 13,5 |

| Magnetic strength/thickness | mm | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 | 7,9 |

Mechanical drawing

Versions 150 - 1000 mm

Recommended sealing ring:

- PARKER 6-349 15,4 x 2,1, Viton 90° SHA

Versions 1250 - 1500 mm

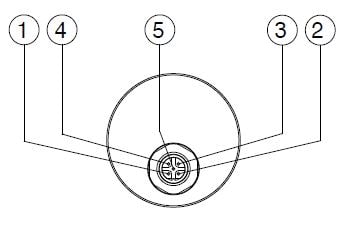

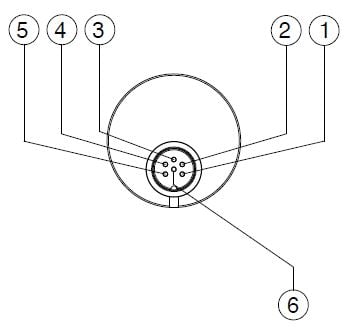

Pin assignment

| 5-Pol M12 | 6-Pol M16 | |

| Output signal 1 (+) | 1 | 1 |

| Output signal 1 (GND) | 2 | 2 |

| Output signal 2 (invers) | 3 | 3 |

| Output signal 2 (GND) | 2 | 4 |

| Power supply + | 5 | 5 |

| Power supply GND | 4 | 6 |

Standard: 3 m cable, 4-wire, unshielded

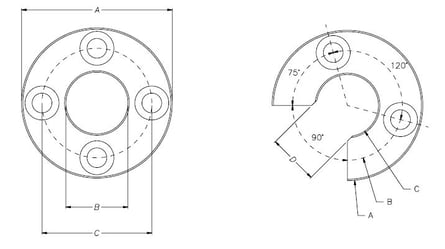

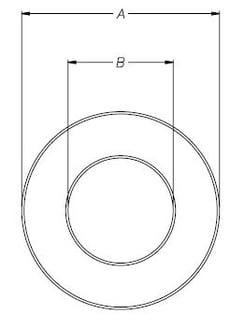

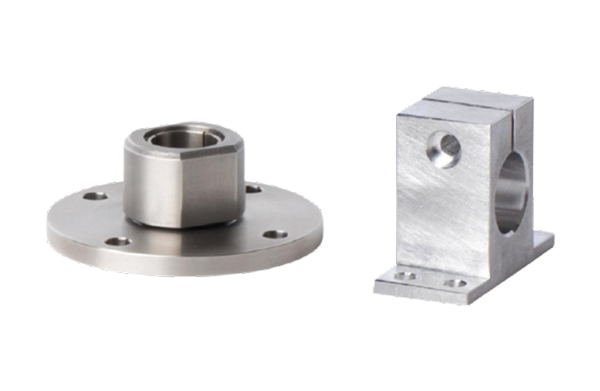

Position magnets

| Version A | Version B | Version C | |

| AD [mm] | 32,8 | 32,8 | 25,4 |

| ID [mm] | 13,5 | 13,5 | 13,5 |

| Bolt circle [mm] | 23,9 | 23,9 | n.a. |

| Strength [mm] | 7,9 | 7,9 | 7,9 |

The position magnets of version A and B are supplied including the screw connection material (M4).